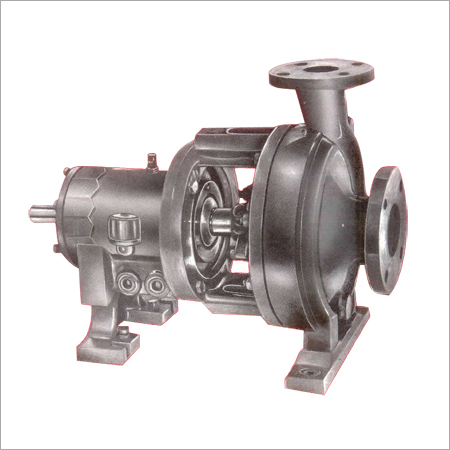

Chemical Process Pumps

Chemical Process Pumps Specification

- Max Suction

- Up to 8 m

- Speed

- 1450 / 2900 rpm

- Theory

- Centrifugal Pump

- Frequency

- 50 Hz / 60 Hz

- Noise Level

- Low Noise Operation

- Head Size

- Up to 80 m

- Voltage

- 220V / 380V / 415V

- Inlet/Outlet

- 25 mm to 150 mm

- Mounting Type

- Baseplate Mounted

- Caliber

- Custom as per model

- Working Temperature

- Up to 120C

- Flow Rate

- Up to 350 m/hr

- Control System

- Manual / Automatic

- Discharge Pressure

- Up to 8 bar

- Material

- Polypropylene / Stainless Steel / Cast Iron / Alloy

- Structure

- Single Stage

- Power

- 0.5 HP to 50 HP

- Standard

- ISO 2858 / DIN 24256

- Fuel Type

- Electric

- Pressure

- Up to 8 bar

- Usage

- Chemical Handling

- Application

- Chemical Industry, Pharmaceuticals, Textile, Paper, Petrochemical, Effluent Treatment

- Suction Type

- Single Suction

- Seals Type

- Mechanical Seal / Gland Packing

- Pump Type

- End Suction

- Capacity

- Up to 350 m/hr

Chemical Process Pumps Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- 1-12 Week

About Chemical Process Pumps

Our company is reckoned as a well developed manufacturer, supplier and exporter of Chemical Process Pumps. Made of premium quality raw materials and components, these products provide flawless functioning and operation. These products are generally used for processing of different types of chemicals and hazardous liquids. To ascertain their error free construction, these products are duly tested by our team of diligent quality analyzers. Chemical Process Pumps can be availed from us in varied different models and grades as per the requirements of our patrons.

Pump built to American specification ANSI B.73.1, having semi open impeller, radially split casing, back pullout type, suitable to mount mechanical seal, flanges to class 150FF.

-

Capacity : up to 750 m3/hr

-

Head: up to 250 m

-

Temp.: up to 260oC

-

Optional Feature: Jacketed Casing & Stuffing Box Cover, Flanges to Class 300FF

-

MOC: CI, CS, AISI-304/316/321/347/304L/316L, CD4MCu, CN7M, HASTELLOY-B/C, R-55, ALUMINUM, etc

Versatile Material Construction

Choose from polypropylene, stainless steel, cast iron, or alloy to ensure maximum compatibility with a wide range of corrosive and abrasive chemicals. Material options provide tailored resistance to various process conditions for enhanced pump longevity.

Customizable Capacity and Performance

With inlet/outlet diameters from 25 mm to 150 mm, suction lifts up to 8 meters, and flow rates reaching 350 m/hr, these pumps are designed to accommodate both small-scale and large-scale operations. Variable power options and control systems allow precise adaptation to project requirements.

Compliance and Safety Standards

Our chemical process pumps are manufactured to ISO 2858 and DIN 24256 standards, ensuring international quality, interchangeability, and operator safety. Each unit undergoes rigorous quality checks prior to shipment.

FAQs of Chemical Process Pumps:

Q: How do I select the correct material of construction for my chemical process pump application?

A: Selecting the right materialpolypropylene, stainless steel, cast iron, or alloydepends on the specific chemicals, temperature, and abrasiveness involved. For corrosive environments, polypropylene or stainless steel is recommended, while cast iron or alloy may suit less aggressive applications.Q: What is the installation process for these chemical process pumps?

A: Installation is straightforward due to the baseplate-mounted design. Ensure the pump is securely installed on a level base, connect the inlet/outlet as specified (25 mm to 150 mm), and complete electrical connections as per voltage requirements (220V, 380V, or 415V). Consult the manual for detailed setup and commissioning steps.Q: When should I use a mechanical seal versus gland packing?

A: Mechanical seals are recommended for applications requiring minimal leakage and lower maintenance. Gland packing can be chosen where some leakage is tolerable and cost-sensitivity is a factor. The selection should match your liquids properties and operational budget.Q: Where can these pumps be used within an industrial setup?

A: Chemical process pumps are ideal for chemical industries, pharmaceuticals, textile processing, paper manufacturing, petrochemical plants, and effluent treatment facilities. Their adaptability supports various demanding fluid transfer operations.Q: What are the key benefits of using a centrifugal end suction pump for chemical handling?

A: Key advantages include high efficiency, low noise operation, easy maintenance, and compatibility with a range of chemicals and slurries. End suction design also simplifies piping arrangements and offers space-saving installation.Q: How is flow and pressure regulated in these pumps during operation?

A: Flow and pressure can be managed via manual or automatic control systems. Adjustments may involve throttling the discharge valve, altering pump speed, or integrating automatic controls for process optimization.Q: What is the regular maintenance process for ensuring pump longevity?

A: Routine maintenance involves inspecting seals or packing, checking alignment, monitoring vibration and noise, lubricating bearings, and verifying all operating parameters. Scheduled preventive checks sustain reliability and extend pump service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Process Pumps Category

High Temperature Centrifugal Pump

Minimum Order Quantity : 1 Set

Usage : Other, Industrial

Suction Type : Single Suction

Theory : Centrifugal Pump

Speed : 2900 RPM

Pressure : Other, 16 bar

Vertical Sump Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Industrial/Commercial/Liquid Transfer

Suction Type : Vertical Immersed

Theory : Centrifugal Pump

Speed : 1450 RPM / 2900 RPM

Pressure : Other, Up to 8 bar

Slurry Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Industrial Slurry Handling

Suction Type : Single

Theory : Centrifugal Pump

Speed : 1450 rpm

Pressure : Other, Up to 3 bar

Chemical Centrifugal Process Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Chemical Process Handling

Suction Type : Single stage

Theory : Centrifugal Pump

Speed : 2900/1450 RPM

Pressure : Other, Max. 10 Bar

|

C.P.V. ENGINEER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry