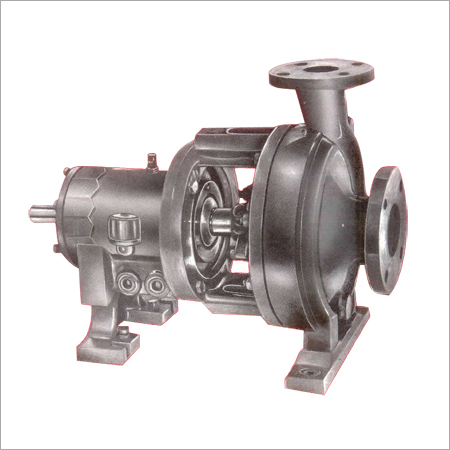

High Temperature Centrifugal Pump

High Temperature Centrifugal Pump Specification

- Voltage

- 415 V

- Discharge Pressure

- Up to 16 Bar

- Caliber

- 50 mm

- Mounting Type

- Base Mounted

- Theory

- Centrifugal Pump

- Max Suction

- 8 Meter

- Working Temperature

- Up to 350C

- Speed

- 2900 RPM

- Noise Level

- <75 dB

- Head Size

- Up to 80 m

- Frequency

- 50 Hz

- Flow Rate

- Up to 150 m/h

- Control System

- Manual / Automatic

- Inlet/Outlet

- 2 inch / 2 inch

- Material

- Cast Iron / Stainless Steel

- Structure

- Horizontal

- Power

- 3 HP 25 HP

- Standard

- IS 5120 / ISO 2858

- Fuel Type

- Electric

- Pressure

- 16 bar

- Usage

- Industrial

- Application

- Thermic Fluid, Boiler Feed, Chemical Transfer, High Temperature Liquid Handling

- Suction Type

- Single Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- High Temperature Centrifugal Pump

- Capacity

- Up to 150 m/h

High Temperature Centrifugal Pump Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Day

- Delivery Time

- 1-12 Week

About High Temperature Centrifugal Pump

Owing to the market knowledge and expertise of our efficient team, we are able to manufacture, supply and export High Temperature Centrifugal Pump. Owing to their high pressure feature, these products helps in maintaining the pressure and flow of liquids in varied industrial applications. In order to to ascertain their effective functioning, these products are duly tested by out adroit quality team.. Packed in special packaging material, High Temperature Centrifugal Pump are delivered to the clients in a safe manner.

Pump built to American specification API- 610, having closed impeller, radially split casing, center line pedestal mounted, suitable to mount mechanical seal, flanges to class 150/300RF

-

Capacity : up to 50 m3/hr

-

Head: up to 45 m

-

Temp.: up to 450oC

-

MOC: CS, AISI- 304/316, etc

Reliable High-Temperature Performance

Crafted to withstand rigorous working temperatures up to 350C, this centrifugal pump ensures stable and safe fluid transfer in demanding environments. Its durable construction and advanced sealing technology make it reliable for continuous industrial use, minimizing downtime and maintenance costs.

Versatile Industrial Applications

From thermic fluid circulation to chemical transfer and boiler feed processes, this pump supports a wide range of high-temperature liquid handling operations. Whether used in chemical plants, manufacturing facilities, or thermal systems, its robust design and high efficiency make it a valuable addition to any industrial setup.

User-Centric Operation and Safety

Designed with both manual and automatic control options, this pump accommodates various operational preferences. Safety is enhanced through its secure mechanical seal and noise level below 75 dB, making it suitable for prolonged use in busy industrial settings.

FAQs of High Temperature Centrifugal Pump:

Q: How does the high temperature centrifugal pump maintain reliable performance at elevated temperatures?

A: This pump is engineered with robust cast iron or stainless-steel construction and a mechanical seal, allowing it to handle working temperatures up to 350C. These features ensure consistent operation and minimize the risk of leakage or structural failure under extreme thermal conditions.Q: What types of industrial processes benefit from using this pump?

A: Industries involved in thermic fluid circulation, boiler feed, chemical transfer, high temperature liquid handling, and other processes requiring efficient high-temperature fluid movement benefit from this pumps robust design and efficient flow capabilities.Q: When is it appropriate to use the self-priming feature of the pump?

A: The self-priming feature is especially beneficial during installation or startup, as it enables the pump to evacuate air from the suction line and prime itself automatically, ensuring quick and reliable operation without manual intervention.Q: Where can this high temperature centrifugal pump be installed?

A: This pump is base-mounted and designed for horizontal installation. It can be integrated into a variety of industrial settings, such as process plants, boilers, and chemical manufacturing units, where high-temperature fluid transfer is required.Q: What is the process for maintaining the mechanical seal on this pump?

A: Regular inspection and timely replacement of the mechanical seal are vital. Maintenance should be performed according to the manufacturers guidelines to ensure long service life, prevent leakage, and maintain optimal performance at high temperatures.Q: How is the flow rate and discharge pressure of the pump regulated?

A: The pump offers both manual and automatic control system options, allowing operators to adjust and regulate the flow rate (up to 150 m/h) and discharge pressure (up to 16 bar) based on process requirements.Q: What are the key benefits of choosing this pump for high temperature applications?

A: Key benefits include reliable operation at temperatures up to 350C, high flow and pressure capacity, compatibility with multiple industrial standards, low noise output, and durable constructionall of which contribute to efficient, safe, and cost-effective industrial fluid handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Process Pumps Category

Vertical Sump Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Industrial/Commercial/Liquid Transfer

Standard : ISO 5199, API 610 (On request)

Max Suction : Up to 7 meters

Voltage : 380V / 415V / 220V (Customizable)

Discharge Pressure : Up to 8 bar

Chemical Process Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Chemical Handling

Standard : ISO 2858 / DIN 24256

Max Suction : Up to 8 m

Voltage : 220V / 380V / 415V

Discharge Pressure : Up to 8 bar

Slurry Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Industrial Slurry Handling

Standard : IS, ISO Certified

Max Suction : 7 meters

Voltage : 415 V

Discharge Pressure : Up to 3 bar

Chemical Centrifugal Process Pumps

Minimum Order Quantity : 1 Set

Usage : Other, Chemical Process Handling

Standard : ISO 5199 / DIN 24256

Max Suction : Up to 8 meters

Voltage : 230/415 V

Discharge Pressure : Up to 10 bar

|

C.P.V. ENGINEER PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry